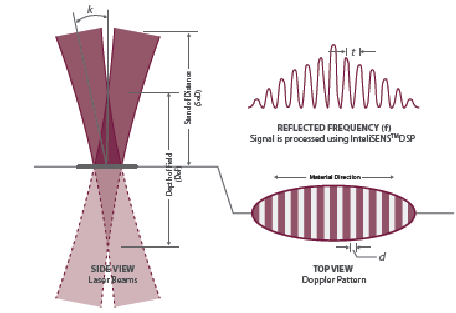

The range of Laser Doppler Non-Contact Speed and Length Gauges provide accurate measurements

in the toughest production environments. The design uses a Class 3R Laser Diode Source

to generate a fringe pattern on the surface of the measured product.

The reflected signal is then collected and processed within the sensor .

The Speed and Length Gauge is an ideal choice for manufacturers producing fast or

slow continuously moving products.

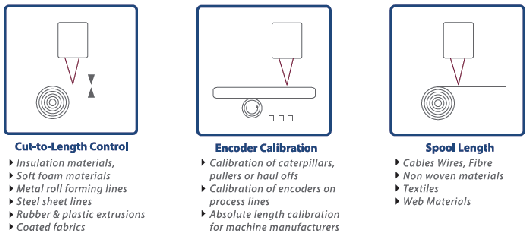

Applications requiring a precise Cut-To-Length pro-duction process benefit from the

highly accurate non slip Laser Doppler measurement.

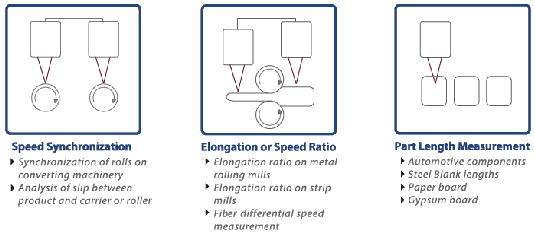

Applications:

- Save material with precise, non-contact, non-slip

length measurement.

- Determine and control slip between material web and

drive elements.

- Monitor and control strip speed in real time.

- Monitor and control the speed of one or more parallel

Webs that need to be synchronised

- Monitor shrinkage or expansion/elongation of the

strip material during the production (rolling) process.

- Monitor and control speed differences between pulp

web and plastic blotter screens in paper production

- Detect and control dressing levels in sheet metal

and foil production. .

- Detect the risks of strip material fracture.

- Cut to length of continuously produced products.

- Replace existing encoder by interfacing with

equivalent quadrature signal into existing controls.

Industries:

Wire, Cable, Pipe, Tube, Fibre, Ferrous & Non-Ferrous Metals, Paper, Corrugated Products,

Web Products, Woven & Non-Woven Products, Rubber Tube & Hose, Building Products,

Plastic Films & Tapes, Cardboard, Glass, Textiles, Foil, Gypsum Board, Fibre Glass,

Composites, Cement sheet, Timber etc.

- 0.05% Accuracy

- Non Contact with Product

- No Slippage

- No Marking or Damage to Product Surface

- No Moving Parts

- No Calibration Required

- Not Affected By Material Surface or Color

- Tachometer Replacement Device

- Robust & Compact Design

- IP65, NEMA4 Protection

- Easy to Install & Integrate

- Economical