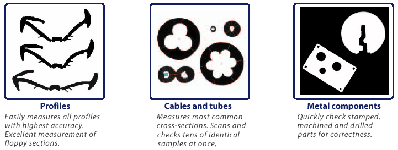

The Vision Profiler system uses flat bed scanners or cameras to measure and tolerance all types of cross sections of small to large objects.

Using either lighting from above or built-

The software offers manual point and click measurements and an optional automatic inspection module for convenient tolerancing using predefined specifications stored in a database.

All images, with or without measurement overlays, can be saved or printed. Results can either be printed or exported to a database

and/or a text file.

VP-

RANGE OF TOOLS

Standard measurement tools

Point-

4-

Maximum clamp (arbitrary,horizontal &vertical)

Minimum clamp (arbitrary,horizontal &vertical)

External edge-

Internal edge-

4-

Maximum clamp (arbitrary,horizontal &vertical)

Minimum clamp (arbitrary,horizontal &vertical)

Radius /diameter (internal &external)

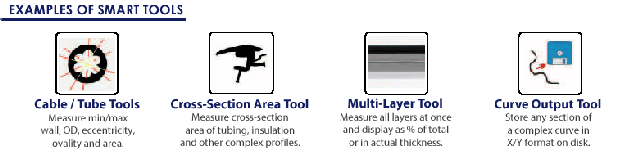

Smart measurement tools

Circular /Figure 8 cable measurement tools

Layer thickness tool

Tube measurement tools

Curve coordinate output tool

Fully automatic inspection and tolerancing

The best way to use the VP3600 software is to use the

automatic inspection procedures (called recipes).

This makes the whole inspection process fully automatic

while removing the possibility of operator errors.

These procedures lock all scanning parameters and

ensure absolutely repeatable independent inspections.

Once created the operator either types in the product code

or selects and runs a recipe to obtain tolerancing and

pass/fail type quality assessments.

-

-

recessed dimensions

-

-

-

-

-

inspection tools

-

-

Section

-

-

BENEFITS