© 2008 Quality In Control Pty. Ltd.

for the Australasian

Manufacturing Industry

Long-

Suitable for high-

The opto-

However, Meterdrive is not just a conventional linear encoder, and offers the user significant benefits over other linear measuring systems : the stainless steel tape can be stretched between two fixed points and does not need to be fixed accurately to a flat base. In this case, the encoder is mobile. Alternatively, the tape can be coiled as in a tape measure with the encoder stationary. This solution, the Rollzam, is particularly useful if there is only one fixed point for the tape, as is the case for fork lifts, table lifts or periodic controls in nuclear power plants.

It is also possible to use the tape with a pulley and counterweight, as a belt between two pulleys, or to move the tape through the fixed encoder. This last solution can be very useful for short distances (such as pneumatic or hydraulic jacks).

The tape is guided in the encoder by 2 pairs of high-

Water and shock resistance, absence of mechanical parts and direct reading via large tape perforations ensure that the system has excellent life and wear characteristics.

Meterdrive is particularly useful as a replacement for conventional chain arrangements, pulleys, etc, where roller slip or wear can cause loss of positioning when using rotary encoders.

Inside the encoder are 4 light-

The output signal can be used with any PLC or proprietary counter. Counters and PLCs have to take all edges of signals A & B into account (multiplication by 4) and must have an external reset. In order to use the high speed operation available with Meterdrive, counters and PLCs must have a counting frequency of 5kHz per channel for Z.201 encoders (1mm resolution) and 50kHz per channel for Z.301 encoders (0,1mm resolution).

- Infrared optical measurement

- Polycarbonate case injected with fibers, completely sealed, light, compact, robust and without moving parts, unaffected by shocks and vibrations.

- Reading speed 10 m/second

- Protection IP 67

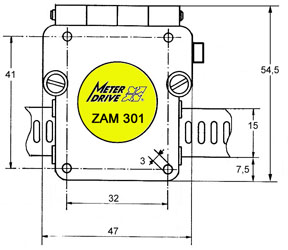

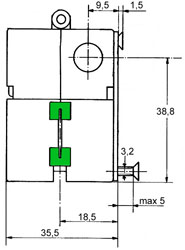

- Version connector, Weight : 90g. Version cable : 350g.

- Power supply 10-

30V DC

- Power consumption 80mA max

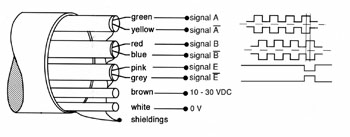

- Incremental output signals A, B and error signal E.

- Working temperature : -

20 to +60°C - Storage temperature: -

40 to +85°C - Protection against static electricity : 1000V, 100pF, 100 ohms

- Protected against polarity inversions, short-

circuit of output signals against each other, 0V, +V

Asymmetric signal encoders

A-

Symmetric signal encoders

A-

Z.201A-

1mm Resolution

Z.301A-

0,1mm Resolution

Z.201-

1mm Resolution

Z.301-

0,1mm Resolution

Output circuit: Push-

Output tension: 10-

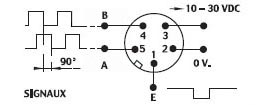

Connection: airtight 5-

Output signals: RS422 driver

Output level 0 : 0,5V max

Ouptut level 1 : 2,5 V mini

Max. load: 10mA per channel

Connection: 2m PVC cable : 8 wires, 4 shieldings, exterior Ø 9mm.

Wiring ; view soldered side

Plan of the connection

Vectral can also supply 2m, 5m or 10m cables with fitted male or female plugs for direct connection to our counters.

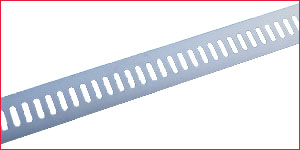

The stainless steel tape is very flexible. making detailed adjustments unnecessary and thus facilitating use of the system (reduced time for engineering departments, installation,….). Thanks to the large size of its perforations (2mm), it is immune to almost all industrial environments.

The tape is usually stretched between two points. Up to 15m, no mid support is required.

Over this length, a support should be positionned every 3-

Tape for Linear encoder Meterdrive

Two types of tape are available

- The Z.200 tape is intended for our Z.201 encoders, 1mm resolution. It is manufactured with an accuracy of ±0,1mm/meter.

- The Z.300 tape is manufactured with an accuracy of ±0,03mm/m. It is the ideal choice for use with our Z.301 encoders if garanteed measures are necessary (ie. metrology).

All of our tapes are manufactured to attain their maximum precision with a tension of 50 Newtons, which can be easily applied with our Z.215 tension system.

For applications not requiring metrology but simply needing a positionning repeatability of 1/10thmm, it is possible to use our more economical Z.200 tape with the Z.301 encoders.

Technical characteristics

Tensile strength

Elasticity limit

Expansion coefficient

Stress deformation

Weight

Thickness

Maximum length

Precision :

Z.200

Z.300

Minimum bending radius

Length minimum for the fixation

2000 Newtons

1000 Newtons

16 µ/m/°C

3,2 µ/m/N

18 g/m

0,2mm

500m.

± 0,1 mm/m à 50N et 22°C

± 0,03 mm/m à 50N et 22°C

5 cm

8 cm

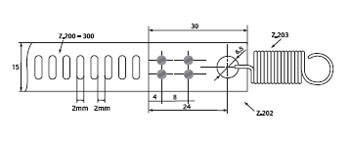

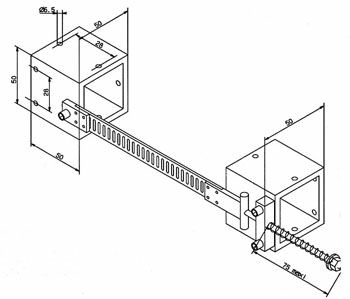

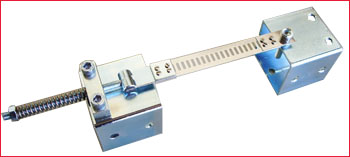

Two systems exist to attach the tape ends

An economic system Z.202 including the 2 pairs of stainless steel plates and the spring Z.203.

A rapid mounting system, Z.215, enables tension adjustment with a compression spring for optimal precision. It can can be bolted to a support in any direction (x, y or z) with just 4 screws.

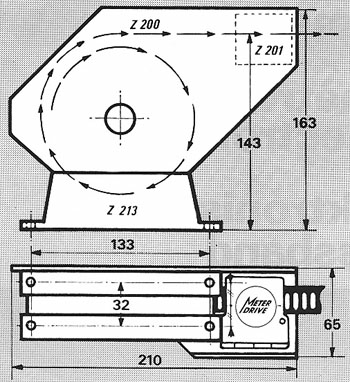

The Rollzam comprises the flexible tape coiled inside a housing and a spring to automatically rewind the tape. The detector head is thus static, protected against the environment, and gives the following benefits : easy mounting, fixed cabling, no tape support required. Standard length : 8 or 15m. The Rollzam base unit can be fitted with any of our (either the Z.201 or Z.301) encoders.

Ideal for : telescopic systems, measuring heights or levels……

Rollzam 213/8

Rollzam 213/8 : 8 meters long

Rollzam 223/15 : 15 meters long